Bucket trucks and cranes have outriggers to ensure they stay stable when the truck is being used. Outriggers act as a balance to keep the bucket truck from leaning too much to one side or the other; and keep them from toppling over. Outriggers lift the entire boom truck off the ground including the tires. Outriggers are necessary for stabilizing a large piece of equipment – such as a crane – lifts loads or personnel aloft, these systems allow employees to work safer, smarter, and all-around more efficiently. When operating equipment outriggers keep your truck stable during a lift by extending outward and by making contact with the ground multiple feet away from the truck. This provides a solid, stable base by distributing the crane’s load over a larger area.

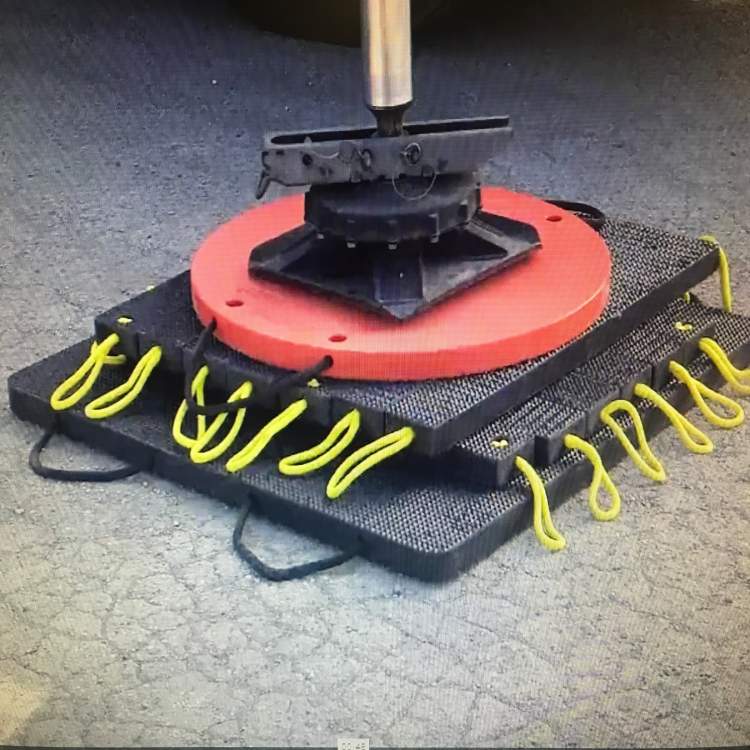

An outrigger pad is a safety device that is used with any equipment that has outriggers, stabilizers, or down jacks. Outrigger pads are placed on the ground under the equipment’s outrigger, float, shoe, or foot, they are designed to stabilize the equipment from toppling over if the ground underneath it gives. If an outrigger pad is not used the pressure of the outrigger on the ground underneath it may shift, be displaced, or collapse. If this happens the equipment can shift or tip the load potentially causing the equipment to topple over which can result in extreme harm to employees. The size and thickness of the outrigger pads are very important for using them correctly. To select the type of outrigger pad you need based on the type of equipment, type of lift being performed, and soil conditions of the worksite.

Using outrigger pads correctly is extremely important for a safe work environment. According to OSHA, 80 percent of crane upsets resulted from human error when the operator exceeds the lifting capacity. Over 50 percent of these errors resulted from improper use of outriggers. There are 250,000 crane operators and there are 125,000 cranes in the construction industry and 80,000-100,000 in general and maritime industries it is extremely important for employees to know and follow all OSHA requirements to perform their job safely.

Divergent Alliance provides the best outrigger pads from Bigfoot Construction Equipment, Inc. Bigfoot Outrigger Pads are the only major manufacturer of both custom composite and wooden outrigger pads. Call 847-531-0559 or submit a contact form to learn more about Bigfoot outrigger pads!

Tips for using outrigger pads

- Setup: Proper setup and leveling are critical to the appropriate function of any style of outrigger system.

- Soil Level: If possible, operators should verify the soil condition of the work area beforehand, this allows them to find out the ground-bearing capacity so they can determine which outrigger pad is adequate.

- OSHA requirements: OSHA 29 CFR 1926.1402, “Ground conditions,” states the following in paragraph 1926.1402(b): “The equipment must not be assembled or used unless ground conditions are firm, drained, and graded to a sufficient extent so that, in conjunction (if necessary) with the use of supporting materials, the equipment manufacturer’s specifications for adequate support and degree of level of the equipment are met. The requirement for the ground to be drained does not apply to marshes/wetlands.” Per 1926.1402(a)(2), “supporting materials” refers to blocking, mats, cribbing, marsh buggies, or similar supporting materials or devices.

-

- ASME Requirements: Operators who do not work in construction should follow: ASME B30.5-3.2.1.5(i) regarding mobile and locomotive cranes states that “[b]locking under outrigger floats when required, shall meet the following requirements: (1) sufficient strength to prevent crushing, bending, or shear failure; (2) such thickness, width, and length, as to completely support the float, transmit the load to the supporting surface, and prevent shifting, toppling, or excessive settlement under load …”

- If soil level is not verified: If you don’t know the ground-bearing capacity beforehand which can happen in several industries such as line work, tree trimming, and some crane work. In this situation, it is recommended that an outrigger pad is at least three times the square surface area of the outrigger shoe or float, provided you are working on Grade A soil conditions. As soil conditions get worse, continue to create a bigger footprint using outrigger pads and cribbing. After the equipment is set up and level, or within the manufacturer’s grade tolerance, and outrigger pads have been deployed, make a dry run of the boom. Use a spotter to ensure the outrigger pads are not shifting, sinking, or sliding into the ground. Then check to see that the equipment is still within-grade or level. If any issues are identified stop and stow the boom. At this time add cribbing, blocking, or more outrigger pads. The pads should be built to support the maximum load of the lift or pick; to displace the weight of the equipment while keeping the equipment level; and to help the crew work safely.

- Determine where power lines are on a jobsite: Know where powerlines are underground and overhead. Operators must maintain proper clearances around overhead power lines as well as identify overhead powerlines while determining minimum approach distance.

- Bridge Requirements: Outrigger pads must not be used to bridge any gaps or span any voids.

- Lift capacity: Operators must know the lift capacity of the equipment and be able to understand how to follow the load chart. This includes accounting for the load being lifted and the rigging being used to lift the load.

- Equipment types: Since different pieces of equipment have different outrigging systems operators must know how to set up many different pieces of equipment:

- An out-and-down or vertical pressure outrigger system is very common on 40-ton cranes and above.

- A-frame or 45-degree outrigger systems are common with bucket trucks and digger derricks.

- You will find combination units with both A-frame and out-and-down outrigger systems on many boom cranes, from 30 tons on down.

- Down jacks typically are found on trailers and heavy-haul equipment.

- Inspection: Outrigger pads should be inspected before each use or setup. After setup use a spotter to inspect the outriggers and the outrigger pads. Check the equipment level and proceed.

- See more information on outrigger pad sizing.

Bigfoot Outrigger Pads

Bigfoot outrigger pads are available in either Custom Composite or Wood in either Econo Southern Yellow Pine or Premium Baltic Birch. Bigfoot outrigger pads are Non-Conductive, Chemical & Oil Resistant, Easy-to-Clean, Storage-Friendly, Durable & Long Lasting. Handles are available in rope, plastic, or metal.

Why choose bigfoot outrigger pads?

In a recent OEM test, Bigfoot Outrigger Pads were the strongest of all the pads tested. Bigfoots Pads are known for their portability, durability, and great value. Bigfoot Outrigger Pads are made in the U.S.A. Bigfoots pads composite in ½” increments to create the best fit & size resulting in reduced weight & cost for the customer.

Custom Outrigger Pads

Need something in specific? Bigfoot can make it for you. Bigfoot provides extremely strong, durable, and cost-effective footing for all your rigging applications.

Common Outrigger Pad Uses

Bigfoot Outrigger Pads are used on Fire Trucks, Utility Trucks, Tree Trimmers, Recreation Vehicles (RV’s) Concrete Pumps, Cranes, and Any Type of Aerial Equipment.

Outrigger pads for large equipment

| SPECS | CUSTOM COMPOSITE | PREMIUM PADS (WOOD) |

| Thickness | 1″-4″ | 2″-4.5″ |

| Max Size | 80″x80″ | 48″x48″ |

| Material | Custom Composite | Baltic Birch, Plywood, Laminated, Bolted |

| Handles | Rope | Rope or Metal |

| Lifetime Guarantee | Yes | No |

‘

Divergent Alliance is a proud supplier of Bigfoot Construction Equipment, Inc. their outrigger pads are fully customizable to your aerial equipment. Want to get a quote or learn more about Bigfoots outrigger pads give us a call at 847-531-0559 or submit a contact form.