What is a Lineman Belt?

Lineman belts are used by workers who climb utility poles. Lineman belts allow linemen to lean back while working with both hands. Lineman belts support the lower back while keeping them secure while working on poles and structures. The body belts attach to pole-climbing straps, which tighten around the pole to prevent workers from slipping down the pole if they fall. Lineman belts also connect to positioning lanyards that keep workers in place while working. Lineman belts have side D-rings, tool loops, and other attachment points for tools. This allows workers to carry their tools with them while working on the pole so they can use both hands and keep tools close by for easy access.

The fit of your lineman climbing belt is extremely important for a lineman’s safety and confidence while working. If your lineman belt is too big it can slide up if you were falling, if the lineman belt is too small the D-rings will pinch your hips making it uncomfortable to work with all day. Most overhead linemen spend hours a day climbing poles, therefore, choosing the correct belt size and belt type for your needs is essential.

Lineman belts have metal D-rings on both sides of the belt near the hips. The metal D-rings on both sides of the belt near the hips attach to a lanyard or anchoring device keeping a lineman secure while working. A lineman belt is worn on the hips with the D-rings positioned in the front of the hip bone.

How to Measure Your Belt Size

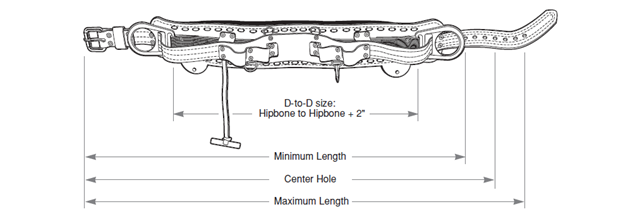

A lineman’s belt is sized by a D measurement, typically 10” less than your waist size. The D measurement is the distance between the D-rings on the belt. To get the size of your lineman belt measure the distance between both of your hips. Begin by measuring around 4” below your hip bone. Bring the seamstress tape around your buttocks until you hit 4” below your hip on the other side. Looking at your seamstress tape the number should be between 18”-32”. A perfect-fitting tool belt will have the D rings pointing straight off the hips and the buckle will be roughly in the center of the adjustment holes.

See images for more details:

Size your lineman belt using a tape measure.

Size your lineman belt using a tape measure.- To obtain the correct D-to-D (D-ring to D-ring) size, measure around the back from hipbone to hipbone and then add 2″ (51 mm).

Lineman Belt Size Chart

| D-to-D Distance | Minimum Length |

|

Maximum Length | |

| 18D (46 cm) | 32″ (81 cm) | 36″ (91 cm) | 40″ (102 cm) | |

| 19D (48 cm) | 33″ (84 cm) | 37″ (94 cm) | 41″ (104 cm) | |

| 20D (51 cm) | 34″ (86 cm) | 38″ (97 cm) | 42″ (107 cm) | |

| 21D (53 cm) | 36″ (91 cm) | 40″ (102 cm) | 44″ (112 cm) | |

| 22D (56 cm) | 37″ (94 cm) | 41″ (104 cm) | 45″ (114 cm) | |

| 23D (58 cm) | 38″ (97 cm) | 42″ (107 cm) | 46″ (117 cm) | |

| 24D (61 cm) | 40″ (102 cm) | 44″ (112 cm) | 48″ (122 cm) | |

| 25D (64 cm) | 41″ (104 cm) | 45″ (114 cm) | 49″ (124 cm) | |

| 26D (66 cm) | 42″ (107 cm) | 46″ (117 cm) | 50″ (127 cm) | |

| 27D (69 cm) | 44 “(112 cm) | 48″ (122 cm) | 52″ (132 cm) | |

| 28D (71 cm) | 45″ (114 cm) | 49″ (124 cm) | 53″ (135 cm) | |

| 29D (74 cm) | 46″ (117 cm) | 50″ (127 cm) | 54″ (137 cm) | |

| 30D (76 cm) | 47″ (119 cm) | 51″ (130 cm) | 55″ (140 cm) |

All measurements are listed in inches and (cm). This table shows the maximum and minimum lengths and center-hole distances for the full range of standard D-to-D measurements. A belt sized for the proper D-to-D size will fit correctly with buckle tongue engaged in the center hole.

For Buckingham Manufacturing sizing see pdf: Buckingham Manufacturing – Body Belt Sizing Chart

For Buckingham Manufacturing sizing see pdf: Buckingham Manufacturing – Body Belt Sizing Chart

Tips for measuring your climbing belt size

- Do not add to your D measurement for winter clothing. The belt has adjustable holes so you can adjust to the proper fit when needed.

- Your D size is not the same as your waist size.

Call Divergent Alliance at (847) 531-0559 or submit a contact form to learn more about our volume pricing for Lineman Belts. We can ship anywhere in the United States.

What Are the Different Types of Lineman Belts?

1.Full-Floating Belt

- Allows the D-rings to shift approximately 4” and the waist strap is stationary.

- D-rings easily adjust to a lineman’s position changes on the pole. Since the positioning strap slides against the pole less frequently, the wear on the strap is reduced.

- Any load or strain on the D-rings will not bind tools in the tool loops.

- Doesn’t allow lateral movement of the belt strap with the tool loops.

2.Semi-Floating Belt

- Does Allow lateral movement of the belt strap with the tool loops prior to wearing the belt.

- Any load or strain on the D-rings won’t bind tools in the tool loops.

- Doesn’t allow lateral movement of the D-rings.

- Semi float belts allow the waist strap to move within the back pad

3.Fixed Belt

Doesn’t allow lateral movement of the D-rings or belt strap with the tool loops.

4. Stacked D-rings & In-line D-rings

Refers to where the D rings sit on a body belt. Can be 2 D-rings or 4 D-rings.

Refers to where the D rings sit on a body belt. Can be 2 D-rings or 4 D-rings.

5.Stacked Body belts

Stacked lineman belts have a secondary set of D-rings positioned above the primary set of D-rings. Since these belts are larger, they offer more support. Stacked 4 D-ring body belts 2 secondary sets of D-rings Positioned above 2 primary sets of D-rings. 4 D-ring stacked body belts are designed to be worn with the belt strap and upper D-rings on the waist not the buttocks like a conventional body belt. Stacked belts make moving and changing positions effortless.

6.In-line D-ring body belts

The primary set of D-rings and they have a secondary set of D-rings positioned in line behind the primary set. The secondary D-rings are flared out to make snapping in when crossing over obstacles seamless. In-line D-ring body belts: The forward body belt D-rings are intended for use as primary attachment points for the wood pole fall restriction devices locking connecting devices. The rear body belt D-rings are intended only for use as a secondary attachment point for connection while transitioning past obstructions.

7.Adjustable Body Belts

Adjustable lineman Belts by Buckingham Manufacturing offers an adjustable upper belt strap and an adjustable lower work positioning D-piece that allows the user to adjust the size of the lineman belt at any given moment. This lineman belt features only four sizes–small, medium, large, and X-large Allowing users to now have a belt that can adjust three to four D sizes. This belt works great for linemen who work in areas with large temperature swings. Having an adjustable belt allows the user to adjust for comfort and their work situation.

Things to Know Before Ordering a Lineman Belt

- Know the requirements needed for the job: governing performance requirements for the equipment needed.

- Select the lineman belt style you want.

- Measure yourself and select the proper body belt size.

Things to Check Before Using Your Lineman Belt

A lineman should inspect his body belt before each use!

- Nicks, cracks, distortion, or corrosion of hardware

- Worn or loose rivets

- Worn material

- Tool loops damaged to allow tools to fall free

- Loose stitching, damaged threads, or burns

- Loose grommets or stretched holes on waist strap

- Broken accessory snap or ring

- Pouch tabs that will not support pouches and tools

Divergent Alliance – Lineman Belt Supplier

Lineman belts are expensive, as a result, you want to make sure you choose the correct belt for what you need and the correct size. Having the correct lineman belt for you allows you to feel comfortable and safe on the job. We have a wide range of lineman belts from the best brands in the industry including Buckingham, Klein Tools, and more. If you follow this guide, we are sure you will choose the correct belt for you but if you need help finding any lineman fall protection give us a call at 847-531-0559 or contact us.

Lineman belts are expensive, as a result, you want to make sure you choose the correct belt for what you need and the correct size. Having the correct lineman belt for you allows you to feel comfortable and safe on the job. We have a wide range of lineman belts from the best brands in the industry including Buckingham, Klein Tools, and more. If you follow this guide, we are sure you will choose the correct belt for you but if you need help finding any lineman fall protection give us a call at 847-531-0559 or contact us.

Divergent Alliance is a Veteran-owned electrical equipment supplier that provides a wide range of lineman tools and equipment for utility workers.